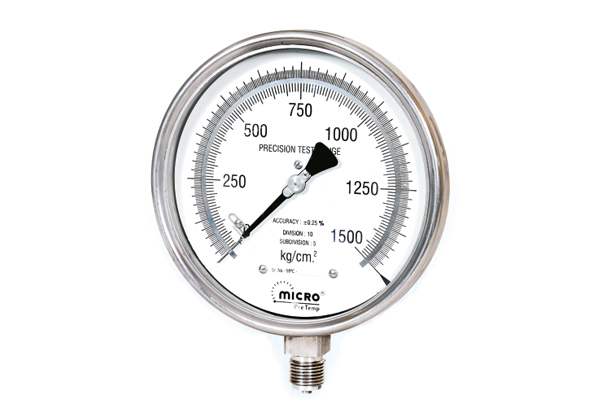

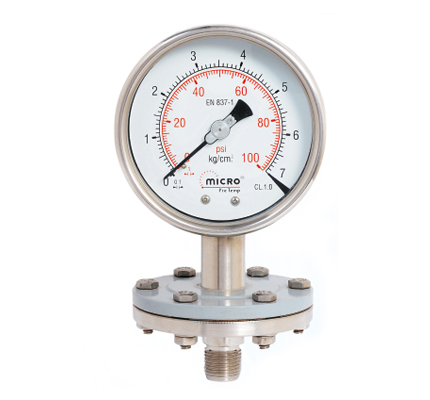

Description

(Confirming to EN-837 & IS-3624)

| Nominal size | Ø 150, 200 & 250 mm |

| Accuracy | ±0.5% of FS (For Test Gauges)±0.25% of FS (For Master Gauges) |

| Case & Bezel | SS 304 case with Snap Action bayonet lock type bezel (SS 316 Optional) |

| Ingress Protection | IP 65 as per EN 60 529 or IS/IEC 60 529 IP 68 as per IS/IEC 60 529 for Ø 150 mm – Optional |

| Pressure element — Bourdon Tube | SS 316 / SS 316L / SS 316Ti / Phosphorus Bronze / Monel 400 / Beryllium Copper (< 100 bar ’C’ shape / ≥ 100 bar helical shape) |

| Over pressure limit | ≤ 100 bar – 125% of FS 100 bar < 600 bar – 115% of FS 600 bar < 1600 bar – 110% of FS |

| Movement | SS 316 / Cu-Alloy High Precision Jeweled bearing with Bi-metal link for Temperature Compensation |

| Socket | Brass / SS 316 / SS 316L / Monel 400 |

| Dial | Aluminium —Pre-coated White with Mirror band & black marking |

| Pointer | Aluminium —Black Finish Knife edge Micro Zero Adjustment |

| Window | 4 mm thick Toughened Glass (Safety / Shatter Proof Optional) |

| Joints | Argon welded |

| Sealing gasket | Neoprene Rubber (EPDM Optional) |

| Blow out protection | Neoprene Rubber on Back of Case (EPDM Optional) |

| Pressure relief | Top of Case with Vent Valve (On Request) |

| Process Connection | 1/4” / 3/8” / 1/2” BSP / NPT / BSPT (Male) M20 X 1.5 (Male), Other Male or Female connection on request |

| Permissible temperature | Ambient : -25’C to 65’C Process : Maximum 650C |

| Type of mounting | Bottom Connection Direct Mounting Back Connection Direct Mounting Bottom Connection Surface Mounting Back Connection Panel Mounting Back Connection Bracket Mounting Back Connection Panel + Bracket Mounting |

| Pressure range | -30” Hg … 0 … 1000 bar |

| Optional Available features | • Liquid Fillable Case for Test Gauges • Customized Scale with different Unit of Measurement or logo • Solid front case (Safety Pattern) • Externally zero adjustable from side or front |

Reviews

There are no reviews yet.